LINEAR SCREENER FOR SEPARATING PLASTIC

LINEAR SCREENER FOR SEPARATING PLASTIC

Publisher: Linear Screener, Linear Screen

Date: Sep 7, 2016

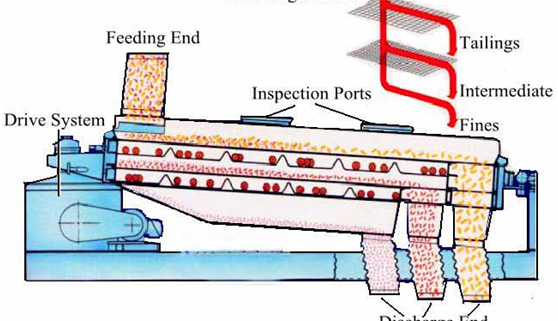

The linear Screener could separate plastic pellet, especially for PVC pellet, Nylon pellet, Epoxy resin particles, it has a high screening efficiency.

MATERIAL CHARACTERISTICS

Plastic pellets are used in making automotive and appliance molded parts, plastic bottles and coating for electric wire. PP Pellets are tablet shaped and PE Pellets are cylindrical. Particale size is approximately 3mm in diameter. The bulk density is approximately 35pcf.

APPLICATION DATA

In the manufacturing process, PP Pellets are screened after under water cutting/pelletizing and drying to remove -1mm fines and +4mm overs. Overs consist of clusters of single pellets that adhere to each other as they discharge from the cutter.

Linear Screener for separating plastic(please click it to unload the running video)

[/av_textblock]

Gyratory Screener Has Been Successfully Ship to Qingdao Port

/0 Comments/by lxyGYRATORY SCREENER FOR PLASTIC PELLETS(PP, PE, HDPE, LDPE)

GYRATORY SCREENER FOR PLASTIC PELLETS(PP, PE, HDPE, LDPE)

Publisher: Gyratory Screener for Plastic Pellets

Date: Aug 24, 2016

MATERIAL CHARACTERISTICS

Plastic pellets are used in making automotive and appliance molded parts, plastic bottles and coating for electric wire. PP Pellets are tablet shaped and PE Pellets are cylindrical. Particale size is approximately 3mm in diameter. The bulk density is approximately 35pcf.

APPLICATION DATA

In the manufacturing process, PP Pellets are screened after under water cutting/pelletizing and drying to remove -1mm fines and +4mm overs. Overs consist of clusters of single pellets that adhere to each other as they discharge from the cutter.

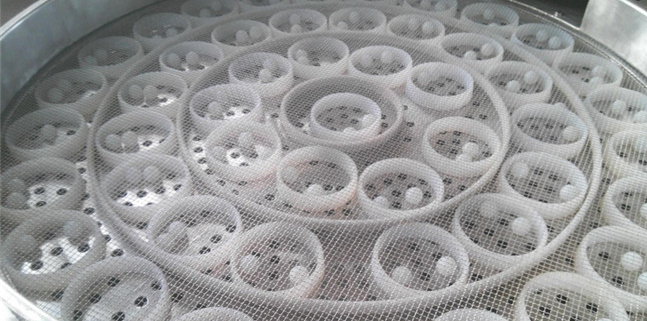

GYRATORY SCREENER ADVANTAGES

Gyratory Screener has own the advantages for separating any pellets that is difficult to screen because of the following features:

1.Adopt Special Gyratory Motion

Gyratory-reciprocating motion provides efficient distribution, stratification, and separation resulting in higher yields and less rejection of good material.

2. Easy Operation

Stable operation, high performance, reduce the screening costs

Only need single operator to inspect and maintain

3. Easy Access Screens

Screens and ball trays are accessible from the side of machine.

No longer need to remove the top cover of machine to access screens and ball trays.

4. Wearable and Reliable

High quality and wearable structure featuring abrasion and corrosion resistant stainless steel.

Circular Screener has been Finished

Circular Screeners Has Been Finished

Publisher: Circular Screeners, Round Screeners

Date: Aug 22, 2016

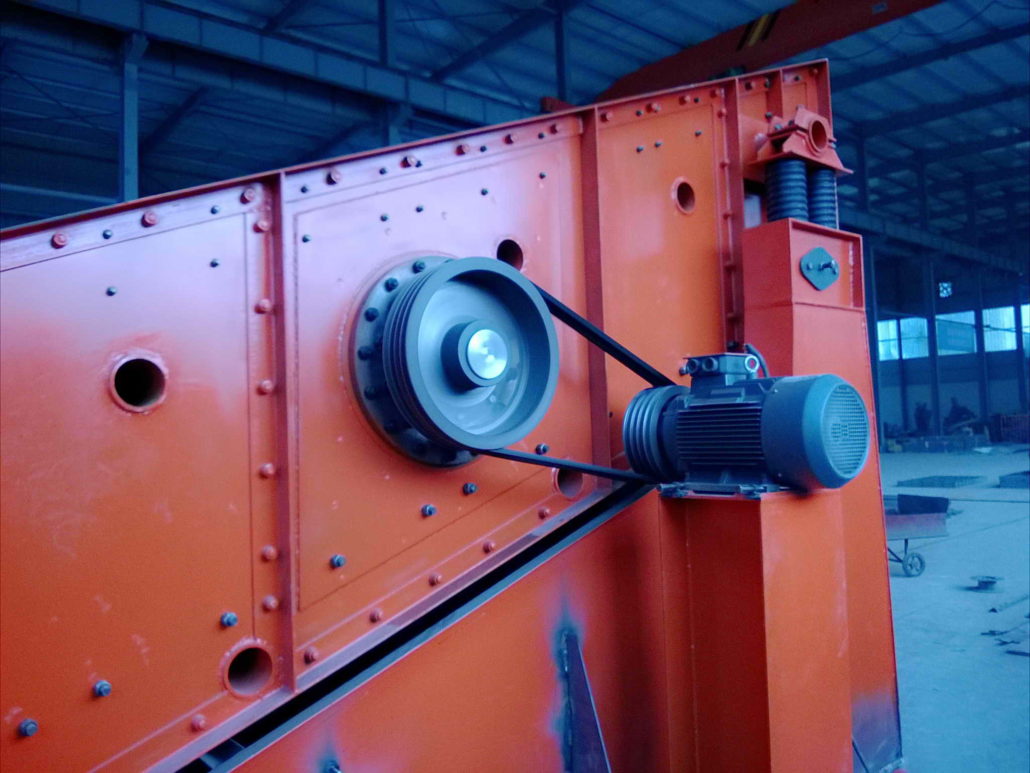

We received good news from production office today and are told that the four circular screeners has been finished. We sign the orders with Russia clients in June and the screeners will be used for separating the coal mining.

Mega Young Cirucalr Screeners has some following advantages:

1. High screening efficiency because of the scientific structure and advanced technology

2. Strong-vibrating force, stable operation, simple structure and easy maintenance

3. Adoption of punching sieve or spring steel screen mesh weaving prevent blockage

4. Long life span, low consumption, little noise