Round Screener with Gyratory Motion

Publisher: round screener

Date: Oct 12, 2016

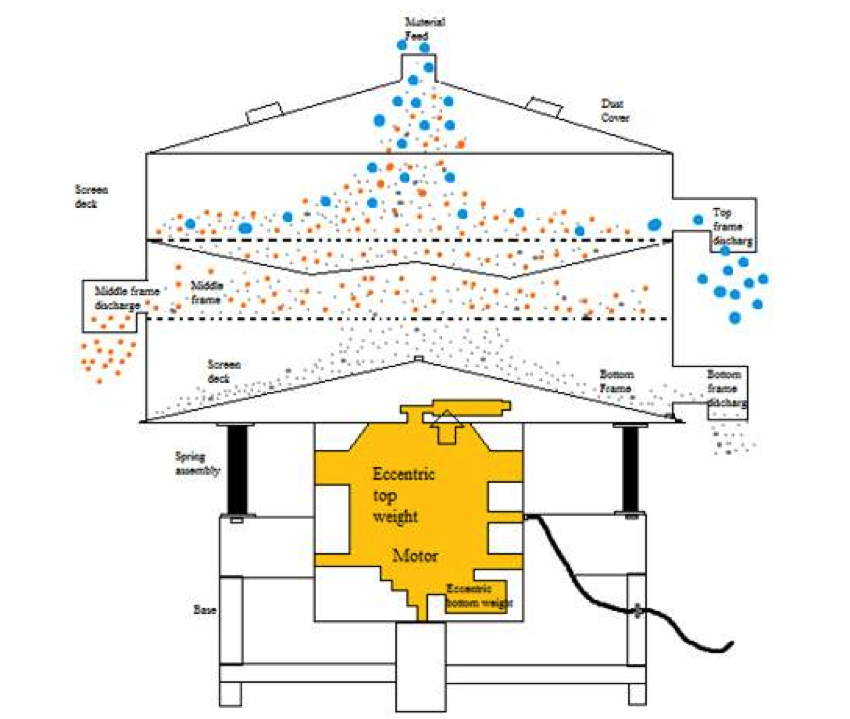

Round screener equipment, used in mechanical screening and sieving is based on a gyratory motion of the machine. Unlike other methods, round vibrating screen operates in a gentler manner and is more suited to handle fragile products, enabling it to produce finer products. This method is applicable for both wet and dry screening.

Round Screener with Gyratory Motion

A distinct difference to other techniques is that the gyratory motion applied here depends on eccentric weights instead of vibrations, which can be varied based on individual process requirement.

schematic_diagram-of-rotary-vibrating-screen

Basic Fundamentals

Round screener contains dcks of screens on top of each other with the coarsest screen on top and the finest below. The feed is inserted from the top and gyratory motion triggers the penetration of particles into the next deck through screen openings.

Casings are inclined at relatively low angles (<15 °) to the horizontal plane, with gyrations occurring in the vertical plane. The eccentric masses can be varied in such as the increase of top eccentric mass leads to an increase in horizontal throw, promoting the discharge of oversize materials. Increment in bottom eccentric mass boosts the material turn over on the screen surface, maximizing the quantity of under-size-material penetration. Over size materials are discharged via tangential outlet.

Schematic diagram of a gyratory motion round screener

round screener working principle

The option to select number of decks enables gyratory equipment to accurately separate materials consisting particles that are very close in size. This advantage is unrivalled and proves to be significant in the powder processing industry where fine materials are involved. High separating efficiency and ease of maintenance puts gyratory screening ahead compared to other processes in terms of product quality.

Existing round screener designs are already on the market, more to come with further development. Recent studies have shown that potential improvements are available for cost-saving and effective separation process.