Analysis of the Reason for Gyratory Screener Mesh Broken

Publisher: gyratory screen

Date: Sep 20, 2016

Gyratory Screen Mesh

Gyratory screener is a kind of precision screening machine, the stainless steel screen mesh is a easy broken part. After a period of working, the users need to change the screen mesh according to the degree of the wear. Now Mega Young Screening will help you analyze the screen broken reason and some items to be noticed.

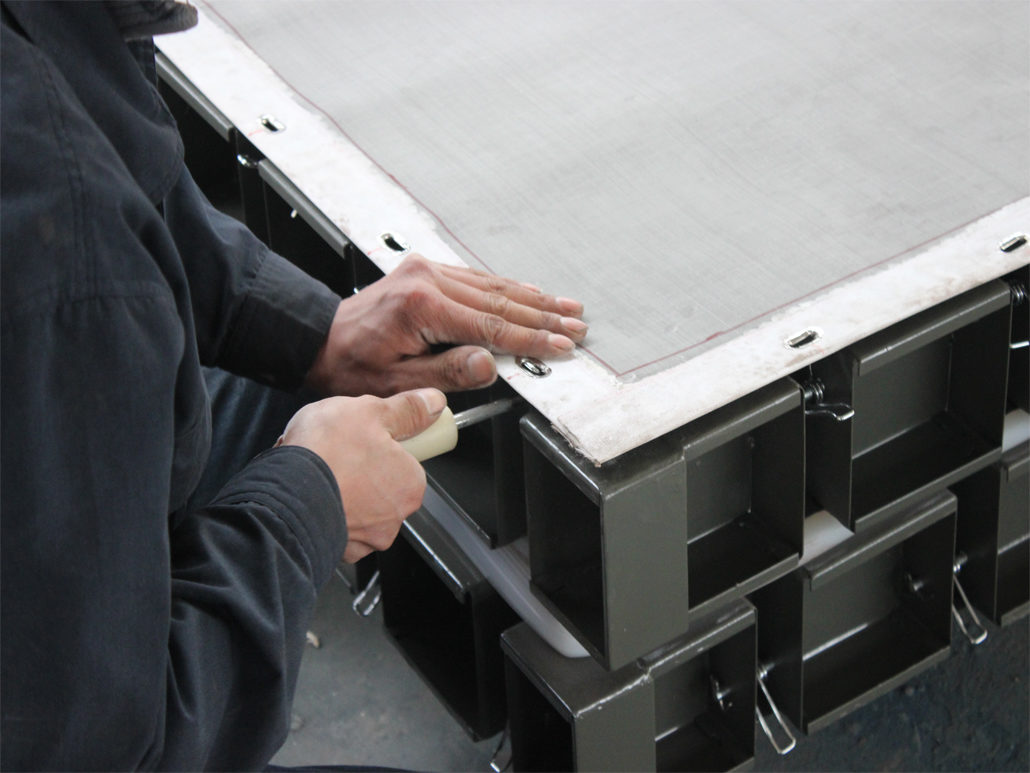

screen installation and change

- Screen Material: the screen mesh material requests sus304 or made of stainless steel woven mesh, sus304 has much nickel, high resistance to acid, metal wire is soft and not easy to be broken and long life service.

- Working screen mesh is not tension and cling to the parent screen so that appear bubble to produce the screen broken.

- While screen machine working, large feeding rate beyond design capacity, which is easy to make the screen broke earlier.

- Strong hardness product is also easy to broke the screen mesh. If the product is strong hardness, we has no way to prevent the screen wear, only choose stanless steel material screen like SUS304, SUS316L. If the screen needs big opening size mesh, we can make into punch screen mesh or add more linear screen mesh to prolong working screen mesh service life.

Mega Young Screening Technology is one professional manufacturer and supplier of the material process and handling, we can provide any solution for our customers with the best service.