MPG Gyratory Screener

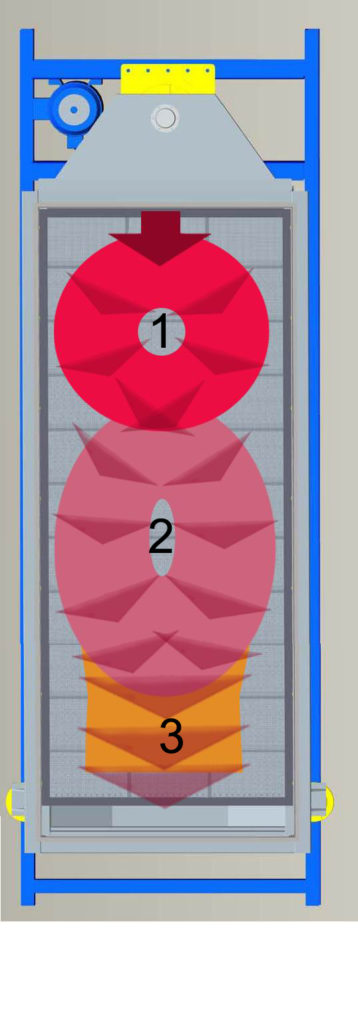

MPG vibratory gyratory screener has the similar features with our M series gyratory screener on working principle, screening efficiency and application range. But the screen deck structure is different with it. The MPG gyratory screener has an unique and economic design which not only reduce the downtime but also increase the productivity.

Gyratory reciprocating motion provides efficient distribution, stratification, and separation resulting in higher yields and less rejection of good material. It no longer needs to remove the top cover of machine to access screens and ball trays. Just needs single operator to manage whatever on maintenance and inspection of the screeners. All screen of the MPG Vibratory Gyratory Screener can be inspected in less than 10 minutes and mesh screen can be changed in 2 minutes, 80% fason M Series gyratory screener.

MPG Vibratory Gyratory Screener Advantages

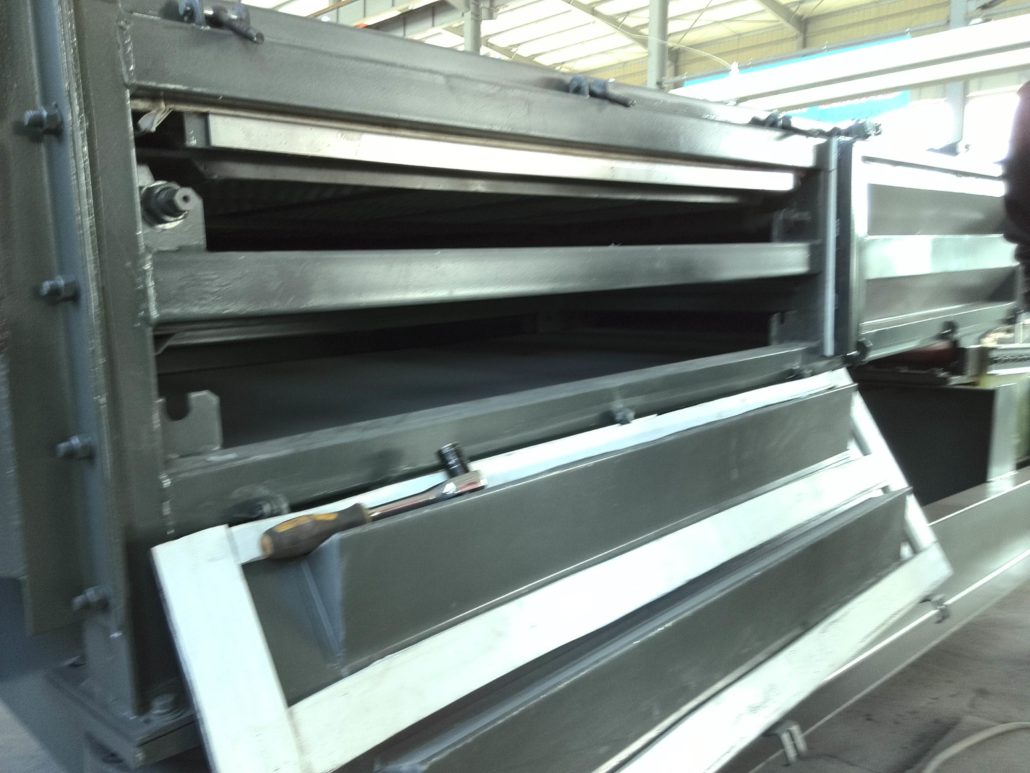

- Compare with the tradional gyratory screener structure, the opening way of MPG Vibratory Gyratory Screener mesh is changed from the top of the screener into both sides of the screener.

- The form of the screener deck is also changed from tradional one layer-one screen mesh into each layer of screen deck is composed of many independent small screener plate, each weight and area of the small screener plate is half and 1/8 of the orginal whole screener plate

- When the screen mesh of the bottom needs to be changed, it is no necessary that remove the top screen deck and cover than before, which improves the working efficiency than before.

- When there is little broken with the screener mesh, it is no nessary to change the whole screener mesh. Just change sigle small screener plate, which improves the working efficiency than before.

- For traditional vibratory gyratory screener, the exchange process of screen mesh very complicated, which waste the production time and lower the working effieiency. Side door access gyratory screener mesh changed very quickly, the time just take less 10 mins.