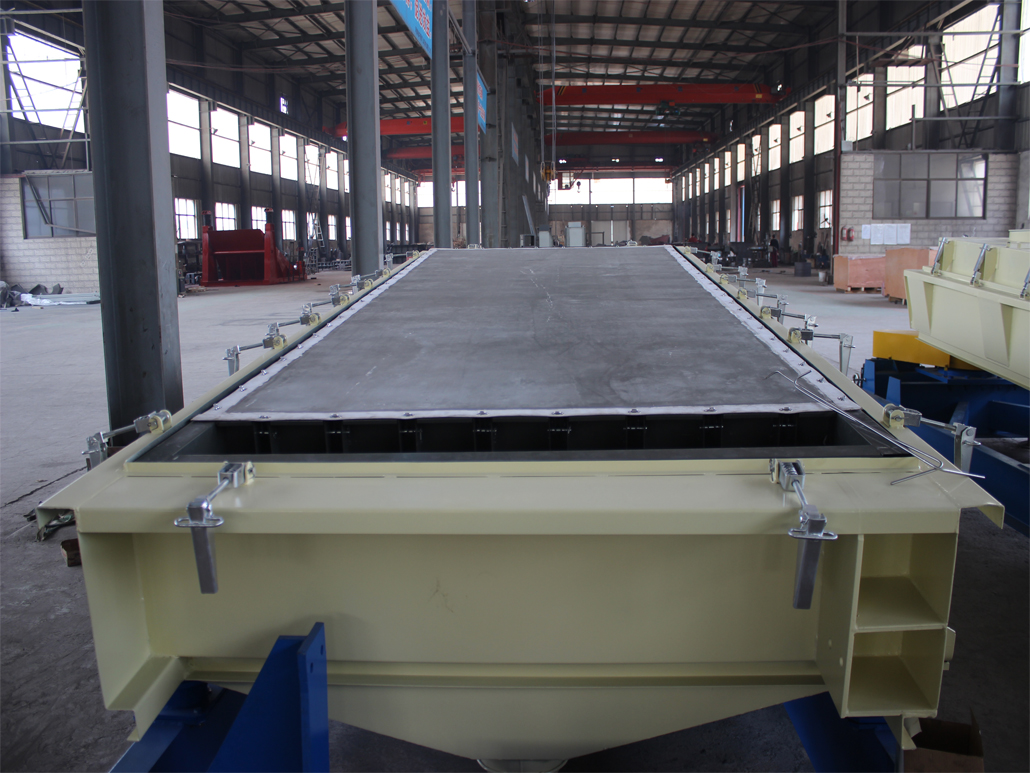

M Series Gyratory Screeners

Mega Young Gyratory Screeners, has the same screener structure and function with the rotex screeners. Comparing with other kinds of screeners, the unique design keep the gyratory screeners has a big capacity and high efficiency operation. Especially for screening the granular urea, perlite, silica sand, activated carbon, sugar, salt such as material particles and fine powders, has a good effects and application.

The production and sales amount of gyratory screeners has been reached hundreds of sets, the performance of the gyratory screeners have been proven by many industries such as mining, grain, food, chemical, ceramics, etc.

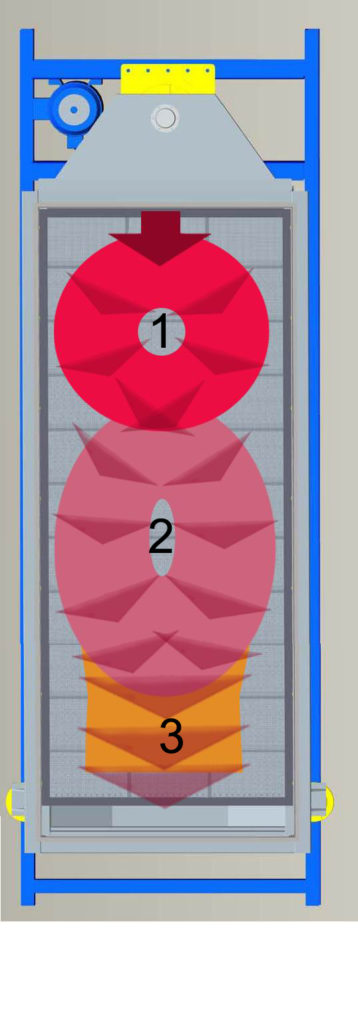

The M series vibratory gyratory screeners spreads the material across the full width of the screen surface, and aggressively conveys material forward. At the feed end in gyratory reciprocation motion to stratifies the material.

Gyratory reciprocating motion gradually diminishes along the length of the machine to an elliptical path Enhances, which enhances the product stratification to conveys material at high capacit. Finally the motion trail nearly becomes straight line at the discharge end. In this way, not only removes the near-size particles, but also improves screening efficiency. Because there is no vertical component ensures material is in constant contact with the screeners surface.

There are many self-cleaning balls in the screen deck of M series gyratory screeners and the balls will impact the working screener mesh when operation for keeping from block.